INFINIT AIR CUTTING COMPRESSED AIR CUTTING

COMPRESSED AIR CUTTING WITH THE NEW AIR CUTTING SYSTEM FROM AIRCO®

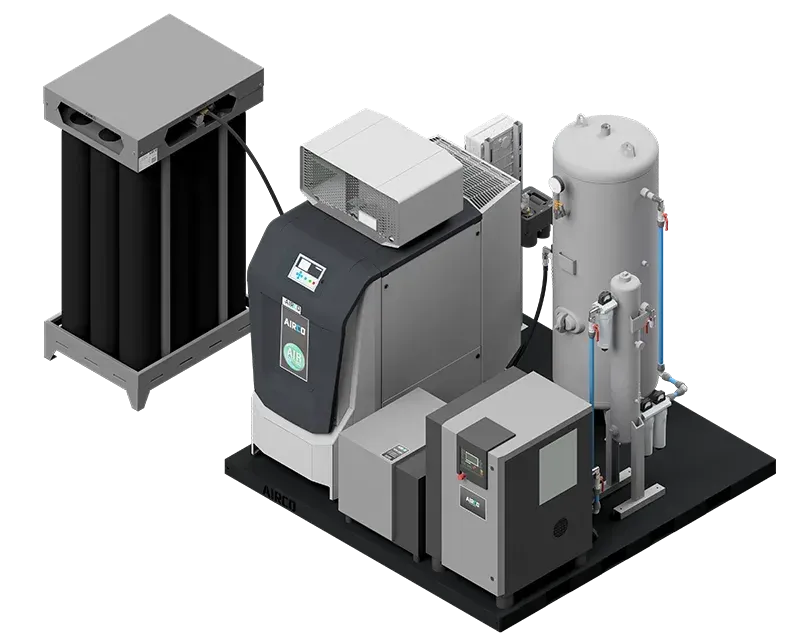

The space-saving, effective and convenient solution for on-site nitrogen production offered by AIRCO® Systems is enjoying huge success. Furthermore, there is also our compressed air cutting system. In addition, there is also our system for compressed air cutting, which, together with all components, is production site in the Rhine / Main region on the prefabricated, modular skids. There is sufficient space for a compressed air preparation unit, product containers, a refrigeration dryer and high-pressure compressors as part of the basic structure, which is always identical

Read more

After pre-assembly has been completed, the systems are extensively tested with regard to their proper functioning and tightness. During this early stage, the settings can be adapted to our customers’ specifications. In this way, we can put the equipment into operation at the customer’s location in record time and can implement the fundamental plug and play concept. Due to its compact construction, the positioning of the system and bundle on-site is easily possible with the use of a forklift truck.

The system for compressed air cutting is then simply connected to the compressed air network, the power connection and the laser application at the customer’s location on site. If required, we can also provide a powerful speed-controlled compressor.

The final step sees our customers receive training directly at their own facility from our technicians, allowing them to plan and monitor their future in-house production optimally.

Production can then begin immediately. Thanks to our high-pressure compressor, we can now compress air at 300 bar in our bundle and, as a result, create a buffer while also comfortably covering your peak consumption requirements. The system is monitored by our fully automatic control unit to guarantee optimal production.

Advantages of Infinit Air Cutting

-

Reduction of cutting gas costs

-

Pressure can be adjusted up to 35 bar

-

Buffer tank can be expanded if necessary

-

Plug and play – Operational immediately

-

Low maintenance requirements

-

Worldwide service

Highlights of the Infinit Air Cutting station

-

Small footprint

-

Fully automatic control

-

Extremely low power consumption

-

CE-certified by our notified body

COMPRESSED AIR QUALITY PER DIN ISO 8573-1 1.4

Class 1: Dirt

Class 2: Water (corresponds to a pressure dew point of +3 °C) refrigeration dryer designed for an ambient temperature of up to +45 °C

Class 3: Residual oil

| Skit-Platform | Volumentrich flow (DL) | Platform dimensions (LxWxH in mm) | Platform weight (approx. in kg) | Power connection |

|---|---|---|---|---|

| AIR CUTTING 15 S | 15 m³/h | 2200 x 2200 x 2200 | 1280 | 50A |

| AIR CUTTING 45 S | 45 m³/h | 2200 x 2200 x 2200 | 1420 | 63A |

We offer a powerful system for compressed air cutting with an efficient high-pressure compressor, dryer, container, 300 bar bundle and a dedicated compressed air preparation unit.

Optional: Efficient and speed-controlled compressor

OFFER – QUERY – ADVICE ON INFINIT AIR CUTTING - Compressed air station

Are you interested in a nitrogen system or the product: INFINIT AIR CUTTING - Compressed air station ? Do you have a query, would like to receive an offer or do you require a consultation? Contact our sales team easily and conveniently or we will be happy to call you back.